Your Path In The Making

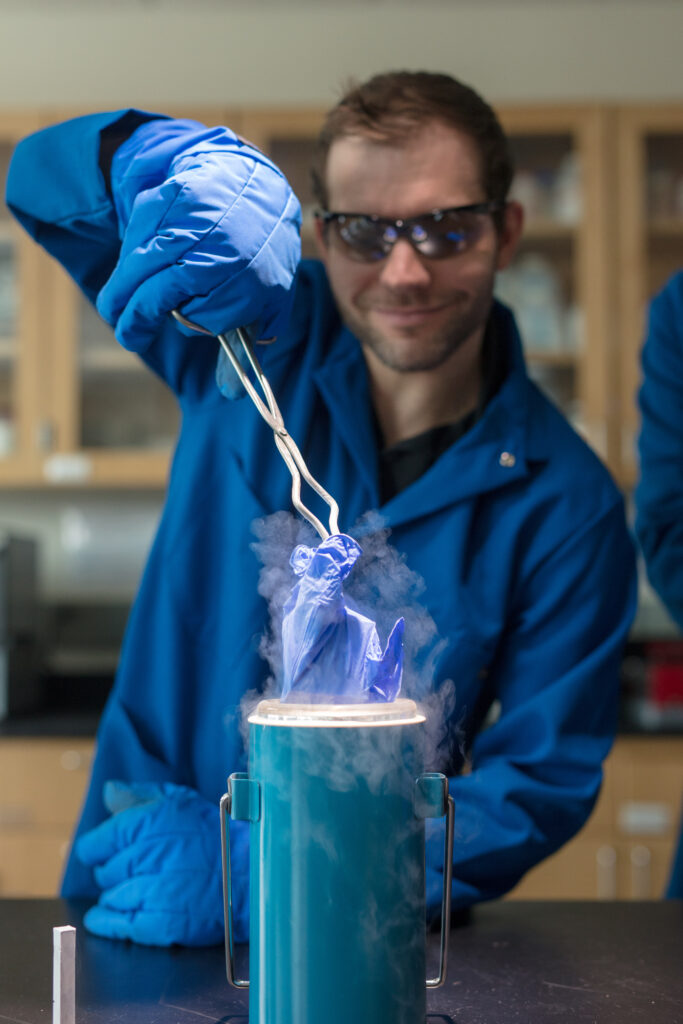

To expand your materials engineering knowledge, you will use state-of-the-art laboratory instruments, advanced fabrication and processing facilities, and cutting- edge computational tools. Our program’s hands-on learning approach will give you a competitive career advantage while developing a scientific and engineering skillset to address society’s greatest needs. Whatever your goals are, your success is important to us.

Personal attention: Building strong relationships with professors and fellow students is key to your success. Our program is designed to encourage interaction.The student-to-faculty ratio is 12:1.The average class size is 30 students, and the average lab size is 15 to 20 students working in teams of 2 to 3.

Undergraduate students have the potential to earn competitive pay while taking courses and serving as research assistants with our amazing faculty. A few of their research areas include biomaterials, biomedical engineering, energy and sustainability, aerospace, additive manufacturing, and defense.

Strong research program

Our faculty work on incredible research projects, offering you an opportunity to obtain valuable hands-on experience before graduation. Some of our research areas include:

- Biomedical engineering: Polymer molecules are arranged and functionalized for biomedical applications like on-demand drug delivery.

- Sustainable engineering: Complex societal problems are solved while conserving resources to achieve sustainability.

- Soft materials: This matter includes fluids, rubbers and gels that can be engineered to be dynamic, mimicking organisms that can change their shape, properties or functionality.

- Additive manufacturing: Novel material processing produces end-use products for aircraft, automobiles, medical implants, and even fashionable wearables with advanced functionality.

Areas of study

While students are exposed to all aspects of materials engineering, you may choose an area of specialization to fit your career aspirations. Emphasis areas include:

- Metals: We need metals to make our world work.They make up critical parts of essentially all modern technologies. By studying the structure and properties of metallic alloys, you will learn how to tailor metals for specific applications, from lightweight metals for fuel- efficient cars to advanced metals for use in high-temperature turbines for airplane engines.

- Ceramics: From their beginnings in clay-based pottery, ceramics are now at the very heart of modern technology, playing critical roles in electronics (computers and cell phones), transportation (batteries and cars), environmental technologies (catalytic converters) and defense (armor).

- Polymers: The medical field uses biodegradable polymers in stitches that the body absorbs, and the automobile industry uses them to replace other materials. Most toys, appliances and recreational equipment contain polymers.They are lightweight, relatively easy to produce, energy efficient, and recyclable.

#MaterialsMatter