A new partnership with Boeing pairs undergraduate students with College of Engineering faculty and Boeing engineers to get hands-on research experience in cutting-edge projects in aerospace engineering, cyber security, autonomous systems, machine learning and more.

“The Boeing Undergraduate Research Fellowship has created opportunities for undergrads to learn research by doing, work on high-impact projects, and get familiar with the intellectual property considerations of industry-backed research,” said Arun Somani, associate dean for research, Anson Marston Distinguished Professor in Engineering, and Philip and Virginia Sproul Professor in Electrical and Computer Engineering.

“What makes this program unique is that each undergrad researcher has two mentors. One is a Cyclone Engineering faculty member in whose lab the student works and gets experience. The second is a mentor from Boeing who advises on the project direction and the practicality of the project for actual industry use,” said Somani. “Boeing Undergraduate Research Fellows also benefit from Innovate at Iowa State’s programming on entrepreneurship, IP management and ethics. Fellows also may get opportunities for summer industry internships.”

“Experiential learning and building relationships are essential to an engineer’s development. This program is another great example where Iowa State students and Boeing engineers come together to jointly learn and research new technologies and approaches to some fascinating aerospace challenges,” said Ben Nimmergut (’01 mechanical engineering), vice president of Boeing Commercial Airplanes Engineering Functions.

Thirteen Boeing Undergraduate Research Fellowships are now underway during the program’s inaugural year. Here are project descriptions and experiences of three of the research mentorships.

New materials for tunable noise cancellation

Yoke Qi Ho, a junior in chemical engineering, is working with Jun Cui, associate professor of materials science and engineering and scientist at the U.S. Department of Energy’s Ames Laboratory, on new engine noise cancellation technology based on the special properties of shape memory alloys.

Right now, noise cancellation is designed for a fixed range of frequencies, but new innovations could tune noise dampening to varying noise frequencies in real time. Ho, under Cui’s mentorship, is developing a shape memory mesh that’s able to change its porosity according to the input electrical current, making its resistance to air flow tuned at aircraft takeoff, cruising and landing.

“This was my first time I’ve been involved in research and this project really helped me realize my passion for engineering,” said Ho. “I’ve learned how to generate big new ideas to explore.”

“The experiences I’m getting in the Boeing Undergraduate Research Fellowship took me beyond what’s in a textbook and put me in the right place to learn from Iowa State faculty and Boeing engineers,” said Ho.

Integrating supply chain and product design

“The engineering problem I’m tackling is a supply chain challenge that many companies struggle with, so I know I’m getting research experience that I will use in my future career,” said Kundan Paudyal, senior in industrial engineering. “Plus, I’m getting the perspective of Boeing mentors who are helping to guide my project and giving me a real-world look at how to be a successful industrial engineer in industry.”

Paudyal is working with Cameron MacKenzie, assistant professor of industrial and manufacturing systems engineering, to design an engineering system that will streamline supply chain processes by integrating supply chain design into the product design phase. Research shows that supply chain costs are substantial – carrying up to 80 percent of a product’s cost – so the benefits of integrating supply chain considerations into the product design process are significant.

“The Boeing Undergraduate Research Fellowship provides a unique research experience for undergraduates by supporting their research with an ISU engineering professor and connecting them to Boeing employees,” said MacKenzie. “The Boeing Fellows learn how to participate in academic research and how to communicate research findings to companies.”

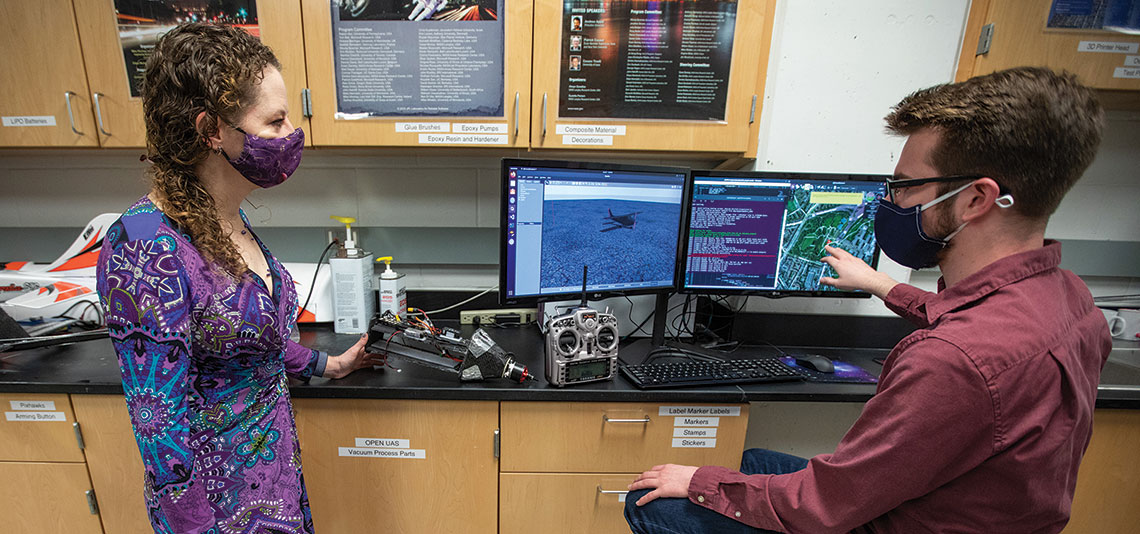

Open-source unmanned aerial systems

Colton Glick, junior in software engineering, joined a 16-member undergraduate research team working on an open-source, 3D printed unmanned aerial system led by Kristin Y. Rozier, assistant professor of aerospace engineering. The goal is to create an accessible option for groups ranging from high schoolers to industrial researchers looking for an easily fixable platform to do research test flights.

“I am working on the electronics and software subteam and am assisting in the development of flight simulation, autonomous landing and obstacle avoidance for the UAS. We saw a lot of significant progress over the fall semester and completed two successful test flights,” said Glick.

“Class projects aren’t nearly as long-term or complex as Rozier’s project, and I have learned so much through working with others on the team who are knowledgeable in many different areas. Having Boeing attached to my research gives it an extra sense of authenticity and importance,” added Glick.

“I’m particularly grateful to Boeing for having the foresight to support undergraduate research,” said Rozier. “It adds tremendously to the undergraduate learning experience and aids in decisions about whether to attend graduate school and for what degree.”